In order to buy, it is important to know:

- The element you are going to measure. If you are dealing with air, gas, oil or other inert elements, you can choose any instrument available in the catalogue, but if, on the other hand, you are in contact with aggressive agents, focus exclusively on completely stainless steel pressure gauges. For oxygen it is essential to request a degreasing operation on the movement.

- The field scales. Since pressure gauges tend to have maximum accuracy in the middle of the dial, we recommend purchasing an instrument that has double the pressure you normally work at (example working at 5 bar, purchasing a pressure gauge with a scale range of 0-10 bar). With this simple precaution will also avoid water hammer when opening the system

- The diameter of the case

- the position of the attachment if rear radial with flange or bracket

- the connection thread. You can easily check it with a caliper: 10mm = 1/8"gas / 12.90mm = 1/4"gas / 16.20mm = 3/8"gas / 20.90mm = 1/2"gas or 1/2 "NPT

- the precision of the instrument. For example, if you purchase a 100 bar pressure gauge with Kl 1% precision, it means that you can encounter an error of max 1 bar in each position of the scale

To find your instrument you can follow 4 paths

-

Use the search field at the top of the page

-

Use the category tree you see on the left, keeping in mind that the pressure gauges are arranged in this order: model > case diameter > position or type of connection

-

Use the site map in the information menu at the bottom of the page

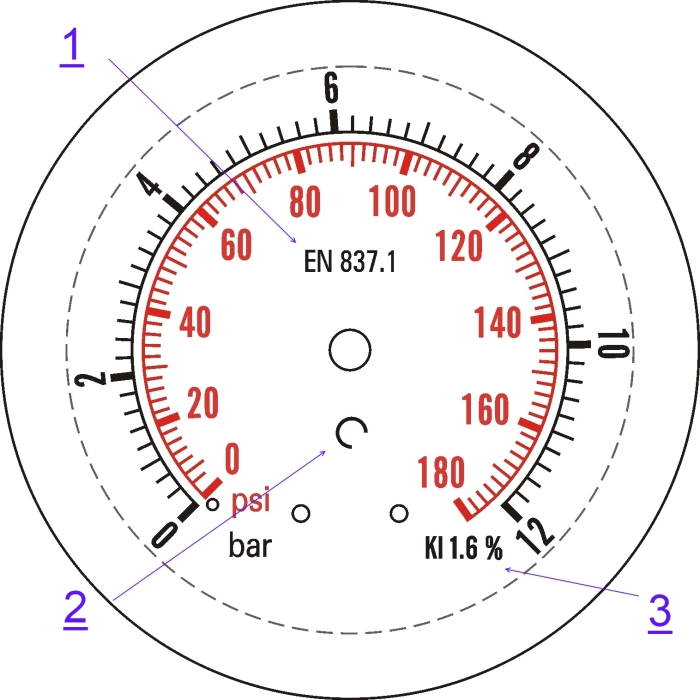

Simplified diagram of pressure gauge operation and details on the dial

Fig.1. The pressure passes through pin 1 and pushes on the C-shaped spring 2 which tends to straighten. The tie rod 3 transmits the movement to the triangular gear 4 which retransmits it to the crown of the hand 5

Fig.2. 1 Reference standard, 2 Indication of the type of spring fitted 3 Accuracy class